Hot-selling Common Grade Silicone - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng

Product Details

Hot-selling Common Grade Silicone - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng Detail:

Client’s request

1. Produce the part as per 3D file and control the accuracy within 0.05M.

2. CMM Inspection refer to the tolerance of 2D drawing.

3. Make sure the assembly is Ok.

Our Analysis

After receiving Client’s drawings and requests, our professional engineers have a the thorough analysis and confirmation that we can produce this part strictly and control all dimensions in tolerance. For making sure the assembly is OK, we requested client to provide the Assembly drawing to check there is no any interference with other components.

Start working

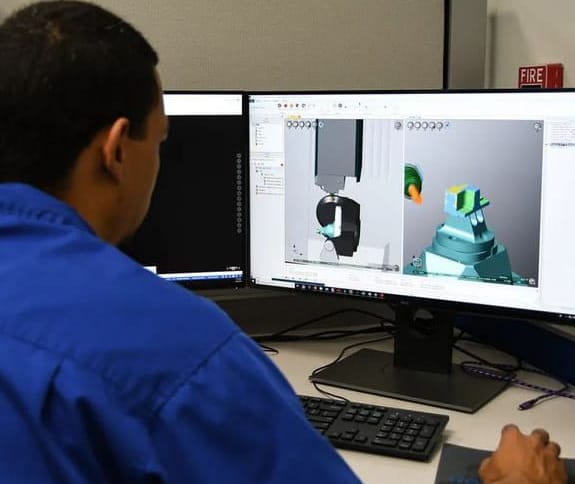

1. Programming

Our CNC programmer is working on setting the work paths of machine.

2. CNC machining

The product is being machined systematically and smoothly as per the program paths we set.

3. Hand Polished

The natural surface of products after CNC is rough and with lot of burrs and knives, Our worker now is using the sandpaper to deburr and polish the surface to have a smooth part without any sharp edges. The part will be sanded from coarse to fine sandpaper (400-1500) level grinding until the surface is smooth.

4.CMM(coordinate measuring machine) Inspection

Our QC is adjusting the CMM machine to have an accurate inspection on dimensional accuracy, positioning accuracy, geometric accuracy and contour accuracy.

5.Shipping

After our QC gave green light on this product,we will ship them out with the strong package to protect product. So that every product will be delivered in the good condition.

Product detail pictures:

Related Product Guide:

owing to very good support, a variety of high quality merchandise, aggressive costs and efficient delivery, we love an excellent name among the our clients. We are an energetic company with wide market for Hot-selling Common Grade Silicone - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng , The product will supply to all over the world, such as: Nigeria, South Africa, Slovenia, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!