Low MOQ for Brass Casting - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng

Product Details

Low MOQ for Brass Casting - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng Detail:

Client’s request

1. Produce the part as per 3D file and control the accuracy within 0.05M.

2. CMM Inspection refer to the tolerance of 2D drawing.

3. Make sure the assembly is Ok.

Our Analysis

After receiving Client’s drawings and requests, our professional engineers have a the thorough analysis and confirmation that we can produce this part strictly and control all dimensions in tolerance. For making sure the assembly is OK, we requested client to provide the Assembly drawing to check there is no any interference with other components.

Start working

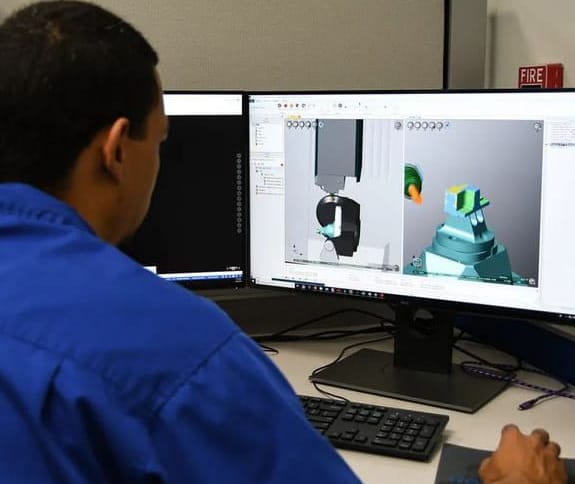

1. Programming

Our CNC programmer is working on setting the work paths of machine.

2. CNC machining

The product is being machined systematically and smoothly as per the program paths we set.

3. Hand Polished

The natural surface of products after CNC is rough and with lot of burrs and knives, Our worker now is using the sandpaper to deburr and polish the surface to have a smooth part without any sharp edges. The part will be sanded from coarse to fine sandpaper (400-1500) level grinding until the surface is smooth.

4.CMM(coordinate measuring machine) Inspection

Our QC is adjusting the CMM machine to have an accurate inspection on dimensional accuracy, positioning accuracy, geometric accuracy and contour accuracy.

5.Shipping

After our QC gave green light on this product,we will ship them out with the strong package to protect product. So that every product will be delivered in the good condition.

Product detail pictures:

Related Product Guide:

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for Low MOQ for Brass Casting - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng , The product will supply to all over the world, such as: Botswana, Belarus, Australia, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.