CNC Router is one of the CNC common machine, it has a lot of function such as: milling, drilling and cutting materials. The main function of CNC router is cut and carve objects out of metal or wood. This article will introduce about CNC routers based on function, materials, applications.

What is CNC Router?

It‘s different with overmolding, CNC Router is a subtractive manufacturing process,that use drill to carve softer materials like wood, soft metals, and, in some cases, steel..A CNC Router typically has a gantry-style construction where the spindle travels left and right along the x-axis and back and forth on the y-axis.But CNC router is different with traditional CNC mill,which can not cut to complex geometries in high-speed, when materials is hard metals. For more information, see our CNC prototypes article.

How does a CNC Router work?

CNC router works is put the material to the machine's available working area and accounting to preset program of CAM to moves, rotates and spins,this program can be created manually for relatively easy tasks or automatically using software.when designer finish the design in computer, router or high-speed drill with a cutting tool will removes material at the locations. Different cutting tools can be used depending on the material and the feature being machined. These tools can be manually changed or in the case of a more advanced machine, such as ATC (Automatic Tool Changer), which can swap out tools by automatic.

What materials is used in a CNC Router?

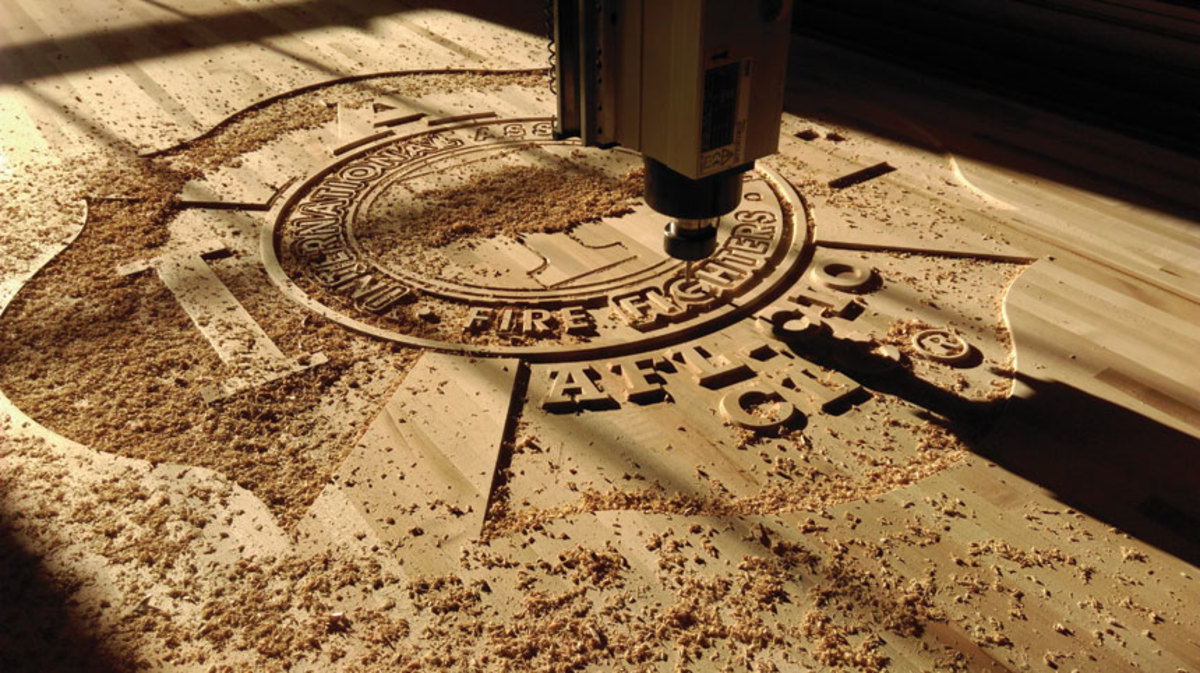

WOODS

wood is the most used material in CNC router, woods across the spectrum of properties are fairly ideal for use in a CNC router.Compared to ordinary steel,Wood has a low hardness and low ductility,so there is little wear on the machine.when using CNC Router, the removed wood will fracture into small chips that make mechanic can easily clear it from the work area, allowing the area to stay relatively clean.

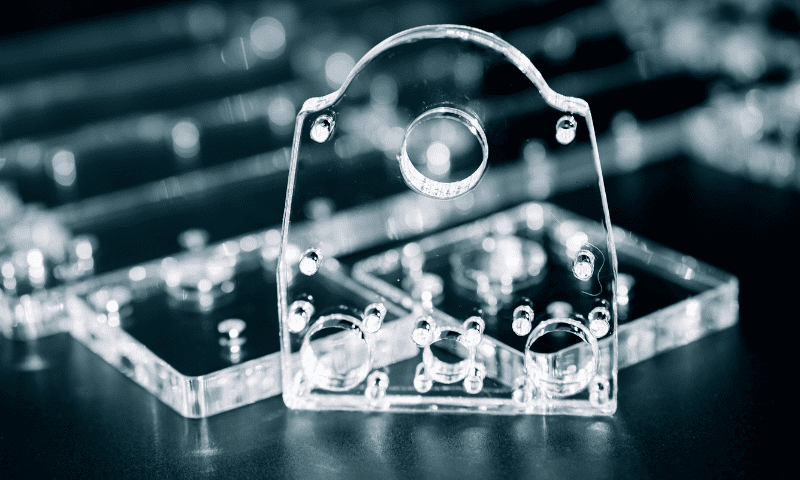

PLEXIGLASS AND ACRYLIC

CNC routers can also engrave and cut on plastic materials such as plexiglass and acrylic. Some of its most common applications include:

•The manufacturing of industrial parts.

•The development of parts for LED lighting.

•The creation of advertising materials.

•The manufacturing of signages and souvenirs.

CNC routers have a better depth capacity compared to other tools. It can create engravings more than 25 mm or 1-inch thick. The hardness of plexiglass and other similar material is also not an issue for this tool since it can cut through them quickly and efficiently.

MATALS

In the vast majority of circumstances, the only metal which suit to cut with a router is aluminum. Some high-Si alloys of Al are very hard, and should only be used in mills.When use regular drill to cut aluminum, Aluminum will produce long curls, which often result in drill jamming if a large amount of clearance is not available.Finally makes machine didn't work. When aluminum must be cut with little tolerance, a special drill should be used.This drill has a "diamond" surface pattern which prevents large area touch with material during cutting.

Please notes that the hardness and cooling of a metal is sensitive to the ambient temperature, so if the temperature in your workspace is not controlled the settings for your router may change.When temperature builds up, the drill may wears out due to softening and causes product change

PLASTIC

Soft and hard plastics like low-density polyethylene and poly methyl-methacrylate are excellent materials to use with a CNC router. They can be made into various parts and tools with multiple applications across various industries.However, you should notes temperature when you cut these materials, so they don’t get deformed due to overheating.

Applications of CNC Router

A CNC router is a computer-controlled cutting device. It can be used for a large range of materials such as wood cutting, MDF cutting, plastics cutting, foams milling, and metals cutting. Here are 6 popular application of your CNC routers.

1, Furniture Making: Using CNC router machine is the best choice to produce large quantities of furniture. And if you want to turn your imagination into reality and make some unique furniture. A CNC router is perfect for the job. CNC router can produce a wide range of personal tailor furniture including beds, dining sets, chairs, staircase, window, modern furniture, office furniture, etc.

2, Cabinet Making: Give your kitchen a make-over with a set of crafted cabinets using your CNC router.

3, Sign Making: A CNC router is perfect for advertising sign carving because it is versatile enough for V-bit carving, 3D carving, fluting, contour profiling, and engraving.

4, Crafts and Art: The range of arts and crafts you can produce with your router is almost limitless, such as jewelry, mirror and picture frames, coins, Christmas decorations, and plaques.

5, Mould Making and Prototyping: CNC foam cutting machine can be used to cut molds from EPS foam, polyurethane foam, EVA foam, plastic, etc. They are very helpful for building CNC foam molds and robot fabrication. More and more digital studio choose them.

6, Design: They are widely used in architectural mill work. Because of the exquisite detail a CNC router can produce, you can make delicate designs for all kinds of unique architectural touches.

Summary

This article presented the CNC router, explained what it is, and discussed things to consider when using it in manufacturing. To learn more about CNC routers, contact us.

Post time: Apr-01-2024