CNC prototyping is an excellent choice because it enables the production of small quantities of prototypes in a shorter time compared to other methods.

Various types of prototypes can be easily manufactured through CNC prototyping. For example, appearance mockup can convey visual information about how the final part will look or behave. However, functional prototypes require higher tolerance and pay more attention to the structure and stability of the product.

This article will introduce the applications of CNC machining prototypes and their pros and cons. Please read on!

CNC Machine

Application of CNC

In almost all precision machining fields, CNC prototype machining is widely used. In many of these industries, there is often a need for a functional prototype, or at least a version that demonstrates how the actual product works. CNC machining of prototypes is the most suitable choice.

CNC Machine

Mechanical parts manufacturing and Mold making

Although the precision requirements of the final product may not necessitate CNC machining, it is indispensable for the production of molds, particularly those with intricate internal shapes and curves. CNC machining stands as the foremost technique in mold manufacturing. While tool steel and stainless steel are the most frequently employed materials for machining molds, aluminum is occasionally utilized as well. Although aluminum is not as durable as steel when subjected to the rigors of injection molding, it serves as a cost-effective alternative for producing batches of injection molded components.

Cast steel molds must be able to maintain their precise dimensions and internal contours over thousands or millions of injection molding cycles, with all the heat and stress associated with them. CNC machining makes it simple to machine these metals to the required tolerances.

Mechanical part

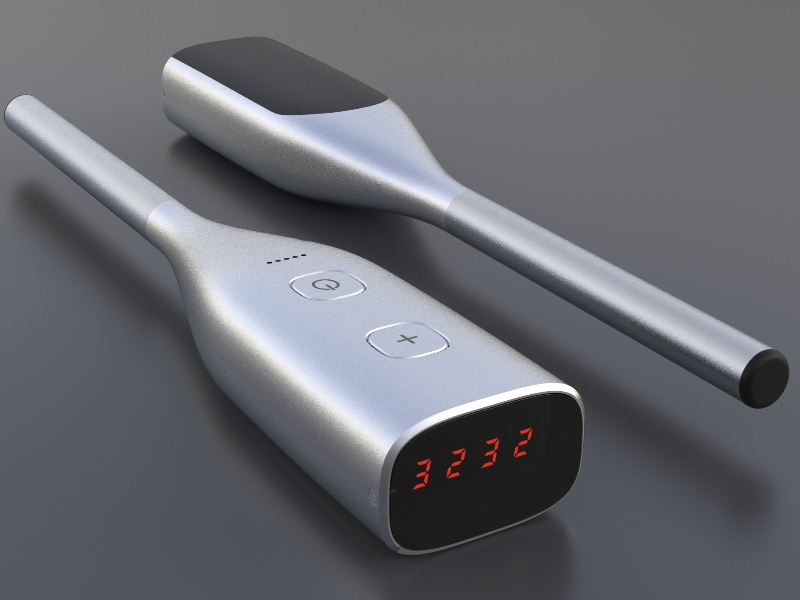

Medical device manufacturing

The field of medicine is progressing swiftly, necessitating the emergence of novel apparatus. Nevertheless, in most cases, medical enterprises require a glimpse of a prototype. This ensures that the product can genuinely fulfill its intended purpose. Considering the significance of human life, there is minimal room for mistakes, demanding that the prototype be an accurate and fully operational replica of the final product.

The creation of this device falls under the responsibility of CNC prototype. These include orthotics, safety enclosures, implants, MRI machines and research equipment, among others.

Medical CNC manufacturing technology can quickly create medical devices. Depending on its complexity, you can make a complete part in just a few hours. In medical emergencies, when the types of parts or components required are difficult to predict, CNC manufacturing enables the rapid delivery of high-quality parts in varying quantities.

Medical instrumentation

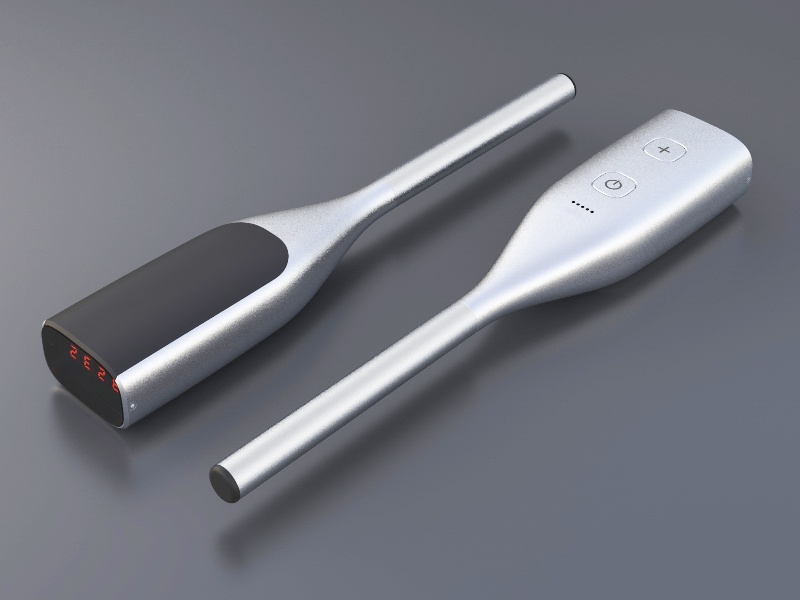

Electronic equipment manufacturing

CNC machining enjoys widespread popularity as a favored manufacturing technique within the electronics sector. This particular method utilizes computerized tools to fabricate components with utmost accuracy. Numerous enterprises employ CNC machining to forge electronic elements, including printed circuit boards and sensors.

Maintaining quality consistency in the electronics manufacturing process is important as it helps ensure that the product meets customer expectations and requirements. This also helps reduce the likelihood of defects and rework, saving time and money.

Adopting CNC machining technology will allow electronics companies to produce more precise products, resulting in high-quality products with reliable performance.

Electronic parts

Learn More

If you ready to bring CNC machine technique into your mold making shop? Please contact us.

Post time: Mar-08-2024