Introduction

ABS is widely used in the injection molding industry, but in applications requiring higher strength and durability, standard ABS often falls short. By reinforcing ABS with glass fibers, its rigidity and dimensional stability are significantly improved, making it more reliable in automotive, appliance, and electronics applications. Glass fiber not only enhances structural strength but also increases heat resistance.

With the growing demand for high-performance plastics, fiber-reinforced ABS has become an effective solution for upgrading injection molding processes. Enhanced ABS not only extends the service life of molded parts but also helps businesses reduce maintenance and replacement costs. This makes fiber-reinforced ABS the preferred material for high-end injection molding applications.

What properties can fiber-reinforced ABS improve?

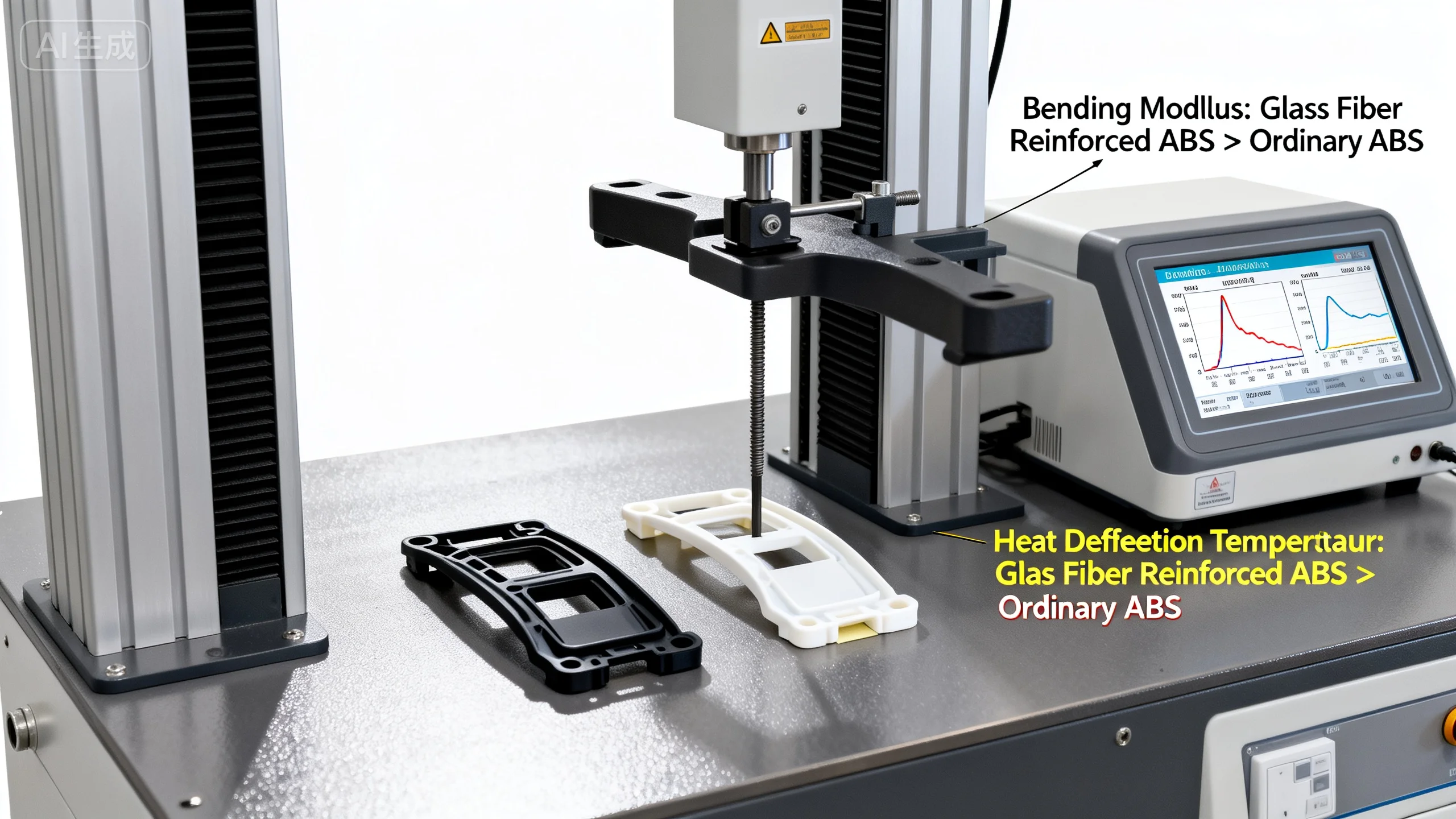

Fiber-reinforced ABS excels in mechanical and thermal performance, particularly in impact resistance, flexural modulus, and heat deflection temperature. Compared with standard ABS, it shows greater reliability and stability under high-stress conditions. Therefore, fiber-reinforced ABS offers superior solutions for parts requiring high strength.

- Structural Strength Increase: Glass fiber boosts rigidity and impact resistance.

- Improved Dimensional Stability: Reduced thermal expansion ensures precision in molded parts.

- Enhanced Heat Resistance: Heat deflection temperature rises significantly, suitable for high-temperature use.

- Longer Service Life: Stable mechanical performance makes parts more durable.

Fiber reinforcement greatly strengthens the overall performance of ABS injection parts.

How much does fiber ratio affect ABS?

As the glass fiber ratio increases, ABS performance improves at varying levels. For example, 20% fiber significantly enhances rigidity, while 40% fiber delivers outstanding strength and heat resistance. However, excessive fiber loading may reduce toughness and increase processing challenges.

- 20% Fiber Effect: Improves rigidity, suitable for general industrial products.

- 30% Fiber Balance: Offers a balance of strength and toughness, widely applicable.

- 40% Fiber High-Performance: Best for high-load and high-temperature conditions.

- Increased Processing Challenges: Higher fiber levels demand tighter process control.

Balancing fiber ratio ensures both performance and processability of ABS.

How does fiber-reinforced ABS affect injection molding?

Adding glass fiber alters the flow behavior and mold wear characteristics of ABS, requiring higher standards in injection molding. During processing, melt viscosity, mold design, and screw wear resistance must be considered. With optimized parameters, fiber-reinforced ABS can achieve stable and efficient production.

- Flow Behavior Changes: Reduced flowability requires higher injection pressure.

- Mold Wear Considerations: Fibers can accelerate mold wear, requiring special treatment.

- Extended Cooling Time: Cooling and shrinkage differ from standard ABS.

- Parameter Optimization: Precise control of temperature and injection speed is critical.

Fiber-reinforced ABS requires optimized processing to deliver the best molding results.

Fiber-Reinforced ABS Performance Comparison

|

Property |

Standard ABS |

20% FR ABS |

30% FR ABS |

40% FR ABS |

| Tensile Strength | Medium | Higher | High | Very High |

| Heat Deflection | Normal | Improved | Noticeably Improved | Strongly Improved |

| Dimensional Stability | Normal | Improved | Significantly Improved | Best |

| Toughness | Good | Slight Drop | Balanced | Lower |

Want to choose the best reinforcement solution for your needs? Reach out now at contact us for a tailored recommendation.

Commercial Value of Fiber-Reinforced ABS

Fiber reinforcement is not only a performance upgrade but also a strategic choice to reduce costs and increase competitiveness. It helps manufacturers ensure quality and recognition in automotive, appliance housings, and precision electronics. From a business perspective, fiber-reinforced ABS opens new markets for high-value injection molded products.

1.Increased Market Competitiveness: Enhanced performance provides differentiation.

2.Production Efficiency Optimization: Proper processing boosts output efficiency.

3.Broader Application Range: More industries can benefit from fiber-reinforced ABS.

4.Added Customer Value: Reduced maintenance cost and extended product lifespan.

Conclusion

Fiber-reinforced ABS is not just a material upgrade but a strategic solution for manufacturers tackling demanding applications. It significantly improves strength, heat resistance, and dimensional stability, creating new opportunities for the injection molding industry. For companies aiming at higher quality and market breakthroughs, fiber-reinforced ABS is a key solution.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Sep-30-2025