What is Injection Molding?

Injection molding is a manufacturing process that involves injecting melted plastic into a mold and allowing it to cool and solidify to form the final product. It is widely used in the production of various plastic items, ranging from small components to large containers and packaging.

Here is the injection molding process:

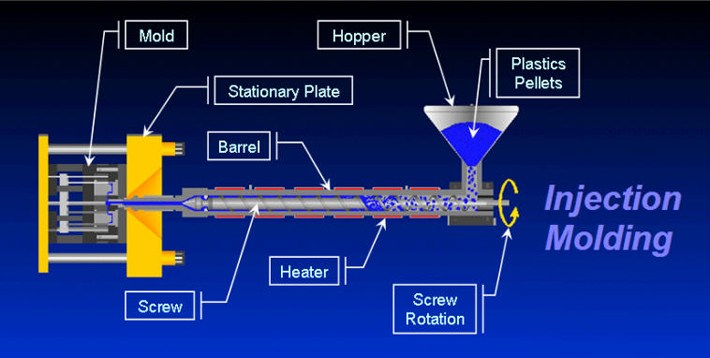

①Mold Design: The mold used in the injection molding process typically consists of two parts: the injection mold and the clamping mold. The injection mold contains an injection system for injecting the melted plastic into the mold. The clamping mold is used to secure the mold and injection system during the injection process.

②Plastic Melting: During the injection molding process, solid plastic pellets or granules are heated and melted to form molten plastic that can be injected into the mold. Heating barrels or heaters are typically used to heat the plastic above its melting point, and the melted plastic is pushed into the injection cylinder through a screw.

③Injection Process: Once the melted plastic reaches the desired temperature and viscosity, the injection process begins. The screw advances in the injection cylinder, extracting the melted plastic from the hopper and injecting it into the mold cavity through a nozzle.

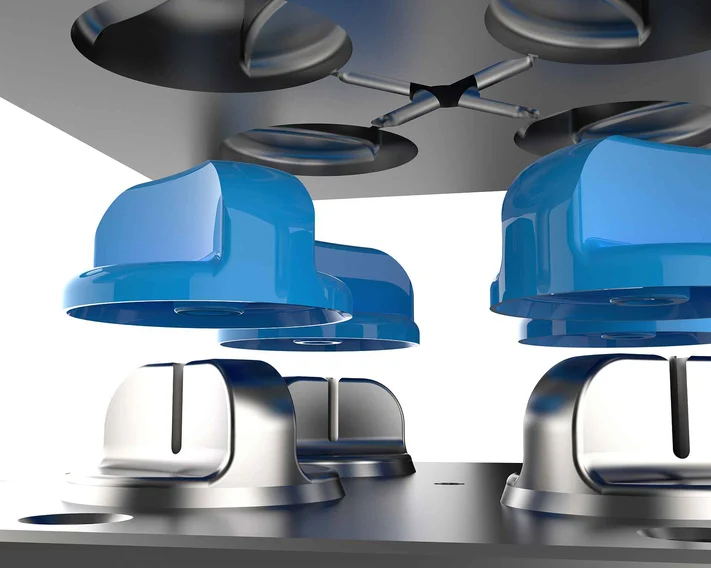

④Filling and Cooling: The molten plastic fills the mold cavity, filling the shape and voids of the mold. Once filling is complete, the plastic starts to cool and solidify within the mold. The cooling time depends on factors such as the type of plastic, part size, and mold temperature control.

⑤Mold Opening and Ejection: After the plastic has cooled and solidified, the mold opens, and the finished product is ejected. The mold opening process is usually controlled by springs, hydraulic systems, or mechanical systems on the mold. Once the finished product is ejected from the mold, the mold is prepared for the next injection cycle.

⑥Post-Processing: After the injection molding is complete, some post-processing steps may be required, such as trimming, removing flash, painting, or assembling additional components to complete the final plastic product.

Why is Injection Molding Important?

Injection molding offers several advantages that make it a crucial process in the manufacturing industry. Firstly, injection molding enables highly precise production of plastic items, ensuring product quality and consistency. Secondly, it is an efficient manufacturing method, capable of producing large quantities of plastic products in a short time. Additionally, injection molding allows for the production of complex shapes and structures to meet diverse industry needs.

Injection molding finds wide applications in industries such as automotive, electronics, medical devices, packaging, and more. From automotive parts to cellphone casings, from plastic bottles to food containers, injection molding technology is ubiquitous.

What kind of customers need to know the process of injection molding?

Product designers: Product designers need to understand the process of injection molding to consider its requirements and limitations during the design phase. They need to be aware of factors such as mold design, material selection, and wall thickness control to ensure that the designed product can be smoothly manufactured through injection molding and meet the expected quality standards.

Manufacturers and product development teams: Manufacturers and product development teams need to understand the process of injection molding to guide their decision-making during the manufacturing process. They need to be familiar with different injection molding options, such as material selection, mold design, and production batch size, to optimize the manufacturing cost and quality of the product.

Procurement managers: Procurement managers need to understand the process of injection molding to evaluate and select suppliers effectively. Understanding the process of injection molding helps them assess the capabilities and technical proficiency of suppliers, enabling them to make informed procurement decisions.

Manufacturing industry customers: Customers in the manufacturing industry need to understand the process of injection molding to collaborate effectively with manufacturers. By understanding the process, they can raise questions, provide suggestions, and participate in product development and manufacturing processes to ensure that the products meet their needs and expectations.

No matter what type of customers you are,If you are looking for a reputable plastic injection mold manufacturer, please contact us for detailed advice.Trust us to meet your needs and exceed your expectations!

Post time: Dec-07-2023