Mold Design and Manufacturing for Plastic Components: Optimization Techniques and Innovative Solutions

In the field of industrial design, the design of plastic components and the manufacturing of molds are crucial stages. This article will discuss the design principles for plastic components,mold design and manufacturing, and share some optimization techniques for design, considerations for mold design, and innovative solutions.

Design Principles for Plastic Components:

Material Selection: Choose suitable plastic materials, such as polypropylene, polyurethane, based on the application requirements, mechanical demands, and durability.

Structural Design: Consider the functionality and assembly requirements of the components, and design appropriate structural forms, dimensions, and connection methods.

Wall Thickness Control: Minimize the wall thickness while ensuring the component's strength and rigidity to reduce costs and material usage.

Bend and Twist Design: Avoid sharp corners and overly complex surface designs to improve mold manufacturing feasibility and component strength.

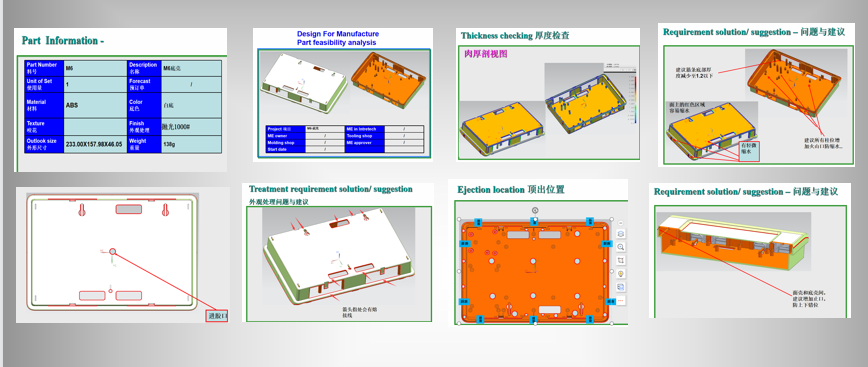

Injection Molding Considerations: Consider injection molding characteristics during the design process, such as gate location, cooling system, and venting system, to enhance molding quality and production efficiency.

Considerations for Mold Design and Manufacturing:

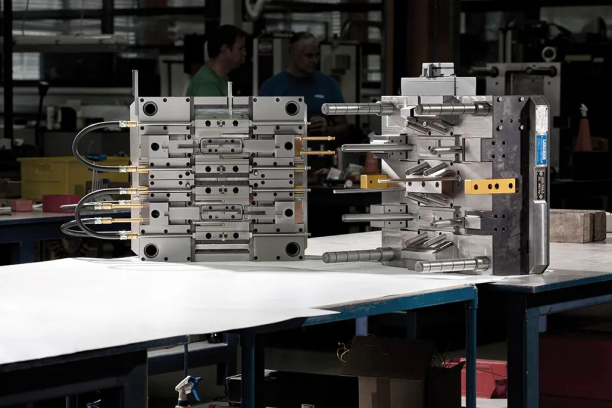

Mold Material Selection: Select appropriate mold materials, such as tool steel, based on component requirements and expected production volumes.

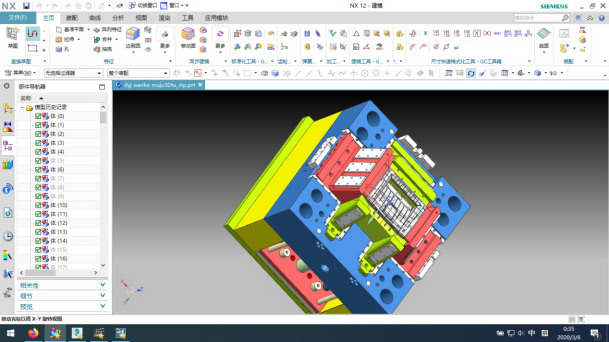

Mold Structure Design: Consider the shape, size, and molding method of the component to design suitable mold structures, including cavity, core, and ejector pins.

Cooling System Design: Design an efficient cooling system to improve the cooling effect during the injection molding process and reduce molding cycle time.

Venting System Design: Design an appropriate venting system to prevent the formation of bubbles and defects, ensuring smooth release of internal gases within the mold.

Surface Treatment and Polishing: Apply suitable surface treatments and polishing based on component requirements to achieve the desired surface quality.

Optimization Techniques for Design:

Emphasize uniform wall thickness, avoiding excessively thin or thick areas to improve component strength and molding quality.

Optimize component geometry to reduce sharp edges, corners, and transitional curves, lowering the complexity and cost of mold manufacturing.

Consider assembly requirements and tolerances to ensure proper fit and connection between components.

Apply lightweight design principles to reduce component weight and material usage, saving costs and resources.

Innovative Solutions:

Utilize additive manufacturing technologies, such as 3D printing, for rapid prototyping and model production to validate design concepts and shapes.

Employ sustainable materials and production processes to promote environmental friendliness and sustainable development.3d printed products for prototyping and modeling are also one of our best service offerings.

By following design principles, paying attention to mold design and manufacturing details, and employing optimization techniques and innovative solutions, the quality, efficiency, and sustainability of plastic component design and mold manufacturing can be improved.

In addition to offering product design services, our company has a dedicated team of professional mold designers. Whether it's designing a new plastic component from scratch or improving an existing one, our designers have extensive experience and skills to deliver high-quality design solutions.

Our design team will collaborate with you to understand your needs and requirements, and provide innovative design solutions based on your specifications. Whether it's plastic material selection, component structural design, wall thickness optimization, or mold design, our designers will offer expert advice to ensure the best design recommendations.

Moreover, customer satisfaction is of utmost importance to us, and we are willing to provide you with free mould/tooling design /DFM services to ensure your satisfaction with the final design solution. We aim to establish a long-term partnership with you and provide ongoing support for your projects.If you have any requirements regarding product design or mold design, feel free to contact our team at any time. We look forward to working with you and providing you with high-quality services.

Post time: Dec-12-2023