What is a welding line

Welding line is also called welding mark, flow mark. In the injection molding process, when multiple gates are used or holes exist in the cavity,or inserts and products with large changes in thickness dimensions, the flow of plastic melt occurs in the mold in more than 2 directions. When two melt strands meet, a welding line will be formed in the part. Strictly speaking, almost all products have welding lines, and it is difficult to completely eliminate them, but only to minimize them, or make them move to insignificant places

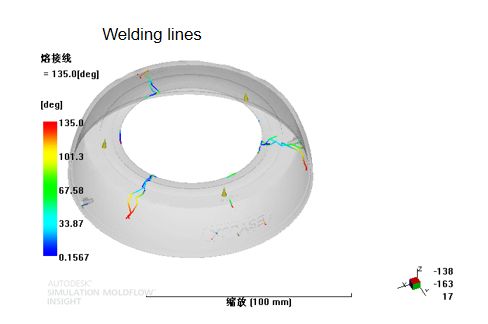

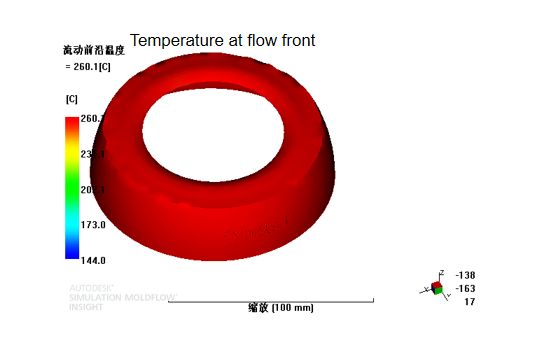

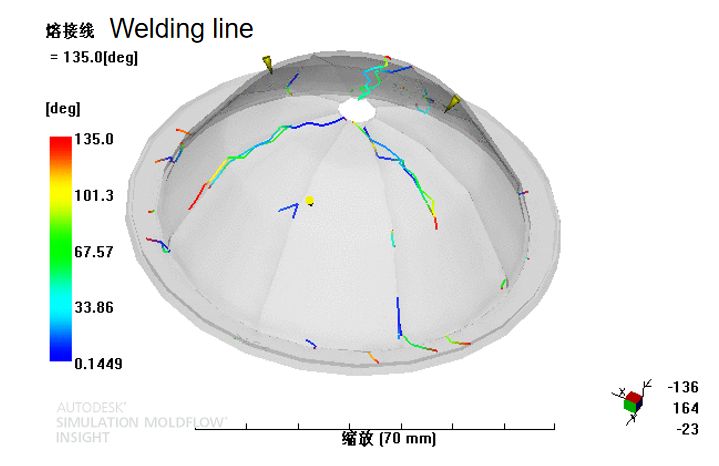

(Welding Line Example)

Reasons for welding line formation

During the cooling process of the two strands of plastic at the position of the welding line, there will be trapped air between the two strands of plastic. The trapped air will obstruct the winding effect of the polymer molecules and cause the molecular chains to separate from each other.

How to minimize the welding line

Product design and mold design

If the appearance and performance of the product is important, the customer and the mold maker should work together ,to minimize the impact of the welding line as best as possible. The customer/product designer should assist the manufacturer in understanding the relevant function of the product and the important cosmetic aspects. The mold designer should then consider the part function and the way the plastic fills or flows into and through the mold during the mold design phase, taking into account the relevant information provided by the customer, increasing the air discharge in the welding line area and minimizing trapped air. Only when the customer and the mold maker work together to understand the product and work together can ensure that the area with least welding line pressure or appear at the least important appearance .

Material selection and processing

Different materials have very different welding line strengths. Some soft contact materials are shear sensitive and welding lines may occur even if the temperature at flow front is not interrupted. This may require a material change to solve the welding line problem.

Injection molding process consideration

The injection molding process can also affect the strength and position of the welding line. Process fluctuations in temperature and pressure will usually have some effect on the welding line.

If possible, make sure that the welding line is formed during the first stage of filling. Welding line formed during the packing time and hold phases are usually problematic. The formation of welding lines during the filling phase often helps to increase the filling rate, thus reducing the filling time and increasing the shear rate. This reduces the viscosity of the polymer during the filling process, resulting in better winding of the molecular chains and easier filling.

Sometimes increasing the packing time or holding pressure will also help. If appearance is an issue, a lower injection rate may help, but usually a higher mold temperature will provide better results. Vacuum venting is a powerful tool that can be very useful in helping with appearance and strength issues.

For more injection molding knowledge, please feel free to contact us.

Post time: Dec-01-2022