Ruicheng is a specialist in the manufacture of injection molding industrial components. Our efficient and accurate injection molding processes allows us to product components of excellent quality and you can accounting to project to customize plastic product belong yourself. We have the capabilities to meet all plastic industrial component requirements in terms of materials, sizes, shapes, tolerances, etc.

Common industrial plastic product

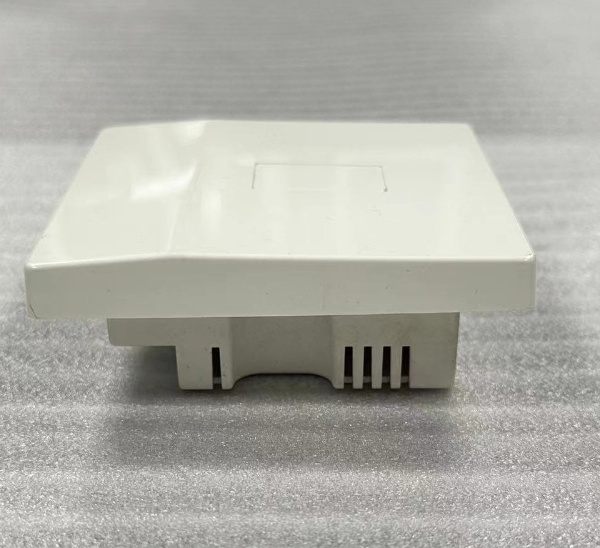

This produce is a Standard Smart WIFI Touch Light Switch housing make by industrial plastic parts and conform to new American standard.

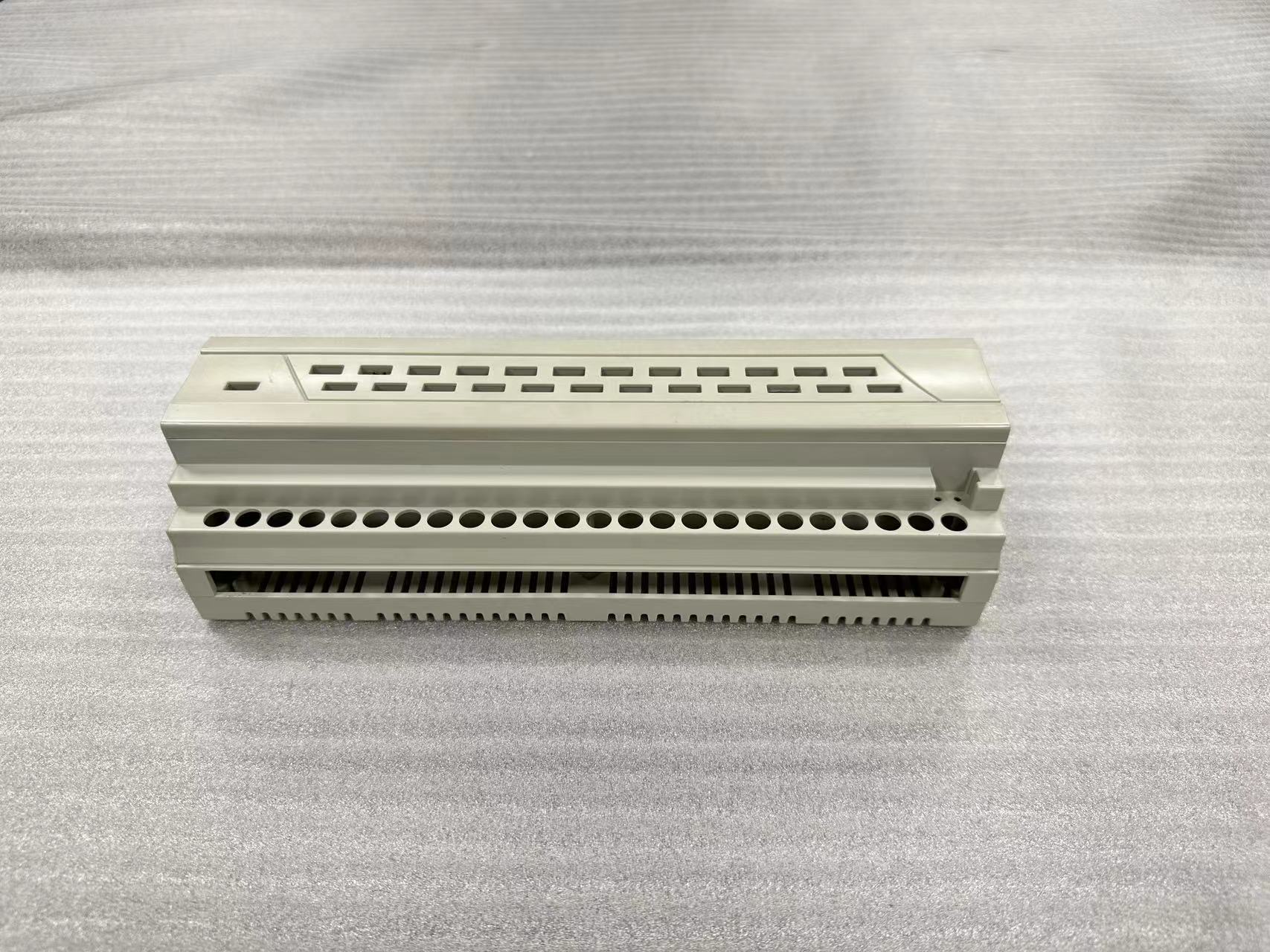

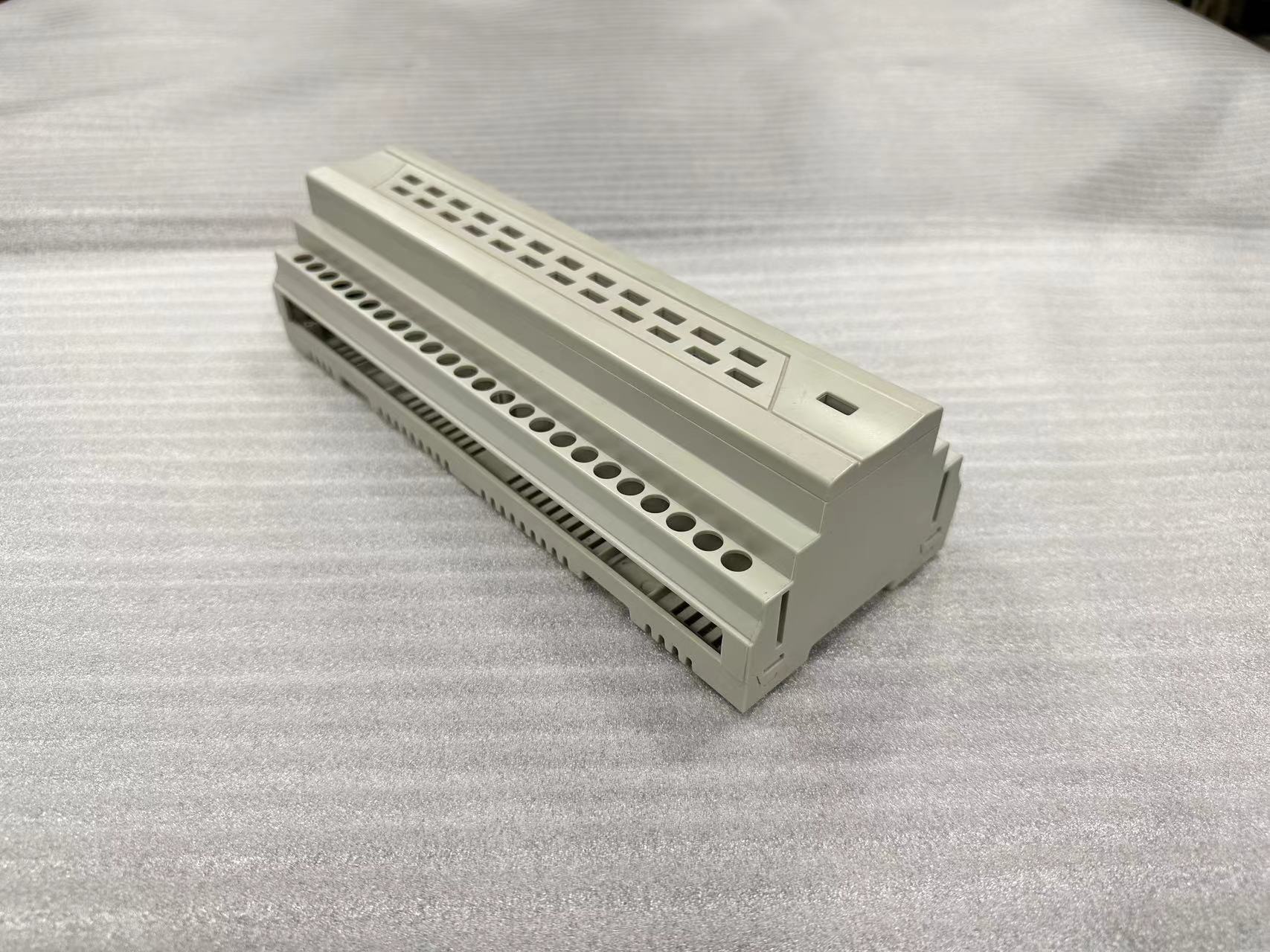

Customized Industrial Plastic Parts with good waterproof and UV resistance, which makes this product function well in outdoor environment.

Made of 100% virgin plastic material, we will conduct strict quality control during the injection molding process, and conduct quality and assembly inspections at the same time. Finally, we will deliver it to you in our good safety packaging.

4.Plastic Overmold Inserts Connector

This customized industrial charging connector is suitable for electrical device supporting. It can provide installation guarantee for your equipment and make it convenient for you to use.

What material you can choose to make industrial plastic product

ABS:

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic that is created using emulsion.With its Strong, flexible, low mold shrinkage (tight tolerances), chemical resistance, electroplating capability, naturally opaque, low/medium cost.

PA66:

PA66 is one of the nylon,it has the same character as nylon,usually apply in handles, levers, small housings, zip ties&gears, bushings.

PC

PC is very tough with temperature resistance and dimensional stability, can be made transparent but in high cost.

PP

PP is in lightweight with heat resistance, high chemical resistance, scratch resistance and natural waxy appearance that is tough and stiff in low cost.

TPU:

TPU is is an elastic material with good resistance to oil, grease, and abrasion.

Common process of industrial plastic product

Injection molding is a manufacturing process used for the mass production of identical plastic parts. It’s a method of plastic injection where molten plastic is inserted into a mold to produce a part in the shape of the mold cavity, creating a physical representation of modeled plastic parts.

The use of injection molding technology to produce industrial products can achieve mass production, which can reduce costs for enterprises, shorten user delivery times, and produce high-quality products.

Additionally, injection molded parts made by injection feature excellent stability and their scrap materials can be recycled, helping to eliminate waste.

Overmolding

Overmolding is a manufacturing process in which one (polymer) material is molded or cast onto another material that may be composite, metal, or polymer in nature. The result is a single, integrated component of two materials which generally have distinct functions in the paired part. The application of this process on plastic industrial parts is very common. Silicone is usually coated on plastic parts to prevent slipping, such as toothbrushes, hammers, electric drills, etc. If it is applied to the housing of electronic components, it is usually for insulation.

Overmolding and injection molding are essentially identical processes used to create (generally) plastic parts. They differ only in that the overmolding process is a secondary operation.

First before we beginning, we need you send the 3d drawing and requirements to us. Professional will analysis this project, evaluate its structures and dimensions to discuss and consider how to design the mold ( such as the injection gate, pins, draft angle etc.)

Second, our worker will accounting the character of your product to setting the injection machine. When the tool closes, signifying the start of the injection molding cycle.

The polymer granules will are dried and placed in the hopper, then they are fed into the barrel, where they are simultaneously heated, mixed and moved towards the mold by a variable pitch screw. The geometry of the screw and the barrel are optimized to help build up the pressure to the correct levels and melt the material.

After filling the mold cavity with plastic, it must be allowed to cool. Water circulated usually as a main way to make a constant temperature as the material hardens.

When the material cools down, it re-solidifies and takes the shape of the mold. Finally, the mold opens and the solid part is pushed out by the ejector pins. The mold then closes and the process repeats.

The finished products will be packed by using plastic bag and put into cartons. If you have a Special packaging requirements, we can also be customized according to the needs of customers .So that every product will be delivered in the good condition.

To learn more about plastic injection craft other industrial product you can contact our sales team to discuss your unique application.

Post time: Apr-15-2024