As we all know Injection molding is one of the most commonly used production processes for plastics that’s why when we make Many intricate parts of automobiles usually use of injection molding processes. In this article, we will take a closer look at the use of plastic injection molding.

In this article, we will take a closer look at the use of plastic injection molding in the automotive component production industry, as well as the types of materials used in the automotive industry and the advantages of injection molding for automotive applications.

Automotive parts

First:The application of injection molding in the automotive component production process

In the early days of the automotive industry, plastic injection molding was not widely adopted. Automakers rely primarily on metal stamping to produce parts, which are bulky and expensive. However, as the automotive industry began to boom, so did the need for more efficient and economical manufacturing methods.

Initially, in the 1950s, injection molding began to be used to manufacture decorative parts. Subsequently, in the late 1970s and 1980s, plastic injection molding quickly became the method of choice for making molds for a variety of automotive parts, including dashboards, headlights, doors and Headlight Cover.

Automotive parts of PC

Entering the 21st century, plastics have become an indispensable structural component of the automotive industry. Plastic parts are lighter than metal parts, making cars more fuel-efficient and cost-effective.

The advantages of injection molding soon made it the manufacturing method of choice in many other industries as well. Today, plastic injection molding is widely used in many industries to produce a variety of parts and products.

Second:The advantages of injection molding for automotive applications

Since the injection molding process was applied to the production of automobile parts, more and more materials are used to produce automobile parts. The following are the materials commonly used by manufacturers.

1.Acrylonitrile Butadiene Styrene (ABS)

ABS,it’s a polymer of acrylonitrile and styrene. ABS has the characteristics of low melting point and high tensile strength.

2.Polycarbonate (PC)

Polycarbonate is a high-performance tough, amorphous, and transparent thermoplastic polymer.it has has the characteristics of High impact strength, high dimensional stability, good electrical properties amongst others.

3.Polypropylene (PP)

Polypropylene is a commodity plastic with low density and high heat resistance. It finds application in packaging, automotive, consumer goods, medical, cast films, etc.

4.Nylon

Nylon is the one of a family of synthetic polymers that are commonly used to make a variety of different types of apparel or bushes or bearings.

5.Polyethylene (PE)

Polyethylene is a member of the important family of polyolefin resins. It is the most widely used plastic in the world, being made into products ranging from clear food wrap and shopping bags to detergent bottles and automobile fuel tanks.

Third:The types of materials used in the automotive industry

Plastic injection molding is a well-established production process in which automotive mold manufactures inject molten plastic into mold cavities. Then, after the molten plastic cools and solidifies, manufacturers extract the finished parts. Although the mold design process is critical and challenging (poorly designed molds can cause defects), injection molding itself is a reliable method for producing high-quality, solid plastic parts with an excellent finish.

Here are a few reasons why the process is beneficial for automotive plastic parts production:

1.Repeatability

In the automotive industry, repeatability is critical, or the ability to consistently produce the same parts. Because automotive plastic injection molding typically relies on a solid metal mold, the final molded automotive parts produced using this mold are virtually identical. There are a few factors that may come into play with injection molding, but if the mold is well designed and precision machined, injection molding is a highly repeatable process.

2.Material Availability

In automotive manufacturing, one of the great advantages of injection molding is the process is ability to accommodate a wide range of different rigid, flexible and rubbery plastics. Automakers utilize a variety of different polymers to meet the needs of all aspects of the automotive industry, including but not limited to ABS, polypropylene, acrylic, nylon, polycarbonate and other materials.

Automotive decorative part (pc+abs)

While automakers commonly use injection molding to mass-produce auto parts, they also view it as a prototyping tool. By using rapid tooling (3D Printing prototype or CNC machining) to create cost-effective aluminum molds, which allowing for rapid turnaround of prototype automotive parts compared to traditional Steel molds have more advantages.

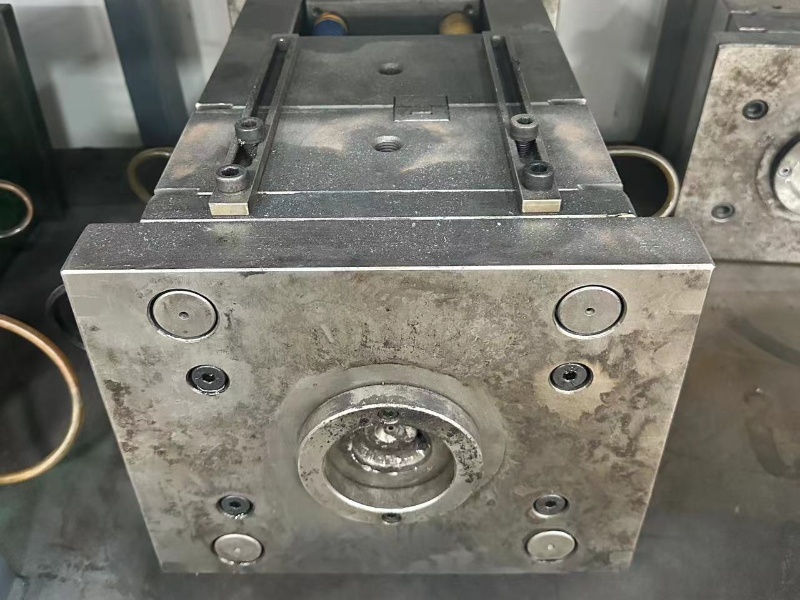

mold

4.High Precision and Surface Finish

Injection molding is ideal for manufacturing plastic parts with relatively simple geometries that achieve a high-quality surface finish. Manufacturers have a variety of surface treatment options when producing parts, including a variety of surface textures (such as glossy, rough or matte) that are applied directly to the mold rather than the molded part. However, different plastic materials can also have an impact on the final surface finish.

5.Color options

In automotive plastic injection molding, it is easy to modify the color of molded automotive parts to fit the vehicle’s color scheme. Unlike other processes, injection molding allows you to mix the dye with the raw material particles before manufacturing begins. This produces a solid, consistent coloration that eliminates the need for painting or staining after molding is complete.

RuiCheng Automotive Plastic Injection Molding Services

we offer professional injection molding services, delivering mass-produced plastic car parts to clients in the automotive and other industries. Our services include thermoplastic injection molding, over-molding, insert molding, and mold making. Our professional automotive plastic injection molding services enable our automotive clients to obtain high-quality molded automotive parts that meet their application requirements.

if you need any services, please contact us!

Post time: Mar-11-2024