Q: Can you confirm the we will own the tooling on completion of final payment?

Ruicheng Answer :It is always the rule that who pays the moulds who own them. We are just the manufacturer and keeper on the toolings.

Q:Can you mark the tooling with their ID so that it is identifiable as their asset?

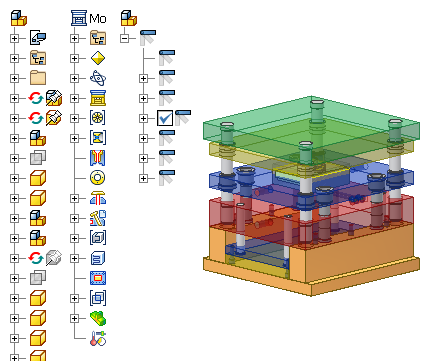

Ruicheng Answer :Yes, we are able to mark the ID that the client need on the tooling outside surface as the following pic.

Q:Can the tooling be moved to the UK /U.S.A/Germany etc in the future?

Ruicheng Answer :Yes, since the toolings belong to the client, you can move it whenever you want. And we are pleased to help to pack them safely in the wooden box as the following pic for its shipment.

Q:What would be the cost of shipping the tooling to the the adress you have specified?

Ruicheng Answer :The shipping price depends on how to ship the toolings to the adress you have specified, by sea or by air, which cannot be calculated now,unless we know how and when to ship. As the shipping price changes every week, and it also depends if the client want to ship all toolings or just one set of them.

Q:Would the tooling be compatible with our local moulder?

Ruicheng Answer :We are not sure about this. As different moulders in different countries will have different mould design even for the same product,and the injection factory are using different brand injection machine for its production, even the same set of mould if to use the different injection machine in different setting up, the finished product will be different,especially the nozzle will be in different size.If the client is considering one day he want the moulds to ship to your local, then it is better for him to check out which supplier he is going to use for these moulds production, by the way, when this order is confirmed, we can offer our moulddesign as their evaluation whether it is OK for their usage.

Q:Please confirm the tooling longevity/shots for each tool?

Ruicheng Answer :

The SPI (Society of the Plastics Industry) classifies injection molds based on their life expectancy:

Class 101 – Life expectancy of +1,000,000 cycles. These are the most expensive injection molds.

Class 102 – Life expectancy not to exceed 1,000,000 cycles

Class 103 – Life expectancy under 500,000 cycles

Class 104 – Life expectancy less than 100,000 cycles

Class 105 – Life expectancy less than 500. This classification is for prototype molds and these molds are the least expensive.

We usually provide advice and quotations according to the customer's life expectancy requirements

Q:What warranty would be provided with the tooling?

Ruicheng Answer :When the toolings are kept in our factory, we can promise it can be produced until its shot life ends.While if the toolings are going to ship to the address you specify, then it will be beyond our control to make sure its shoting life, as how to inject each set of toolings is the main factor to affect its tooling life. And we cannot fix the mould directly when it is damaged there.

Q:Would you insure the tools at your cost for fire, theft, damage and any other eventuality?

Ruicheng Answer :Once the toolings are kept in our factory, it is our responsibility to keep them safe until its shoting life ends,

if unluckily any accident happen here, it is our cost to make the new for the client. which means after the toolings is paid and finsihed, the client just needs to place its production order until the quantities is reached to its shots life.. If the toolings are going to be shipped to your local, sorry that we cannot insure the toolings.

Talk to us about your new project ,free consultation and free DFM

Post time: Sep-05-2022