As one of the traditional processes, stamping is very popular in the customization industry. Especially for manufacturers, the stamping process can bring huge benefits. If you want to know how this is achieved, please continue reading this article.

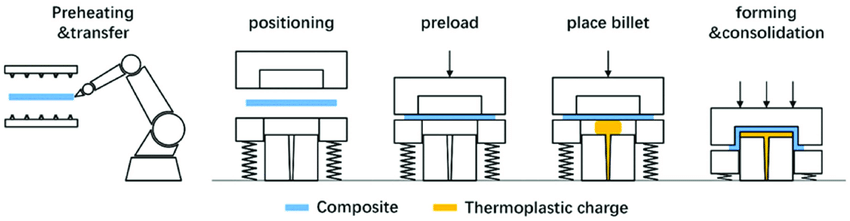

Stamping-also called pressing — involves placing flat sheet metal, in either coil or blank form, into a stamping press. In the press, a tool and die surface form the metal into the desired shape. Punching, blanking, bending, coining, embossing, and flanging are all stamping techniques used to shape the metal.

Before the material can be formed, stamping professionals must design the tooling via CAD/CAM engineering technology. These designs must be as precise as possible to ensure each punch and bend maintains proper clearance and, therefore, optimal part quality. A single tool 3D model can contain hundreds of parts, so the design process is often quite complex and time-consuming.

Once the tool’s design is established, a manufacturer can use a variety of machining, grinding, wire EDM and other manufacturing services to complete its production.

1.Blanking

2.Punching

3.Drawing

4.Deep Drawing

5.Lancing

6.Bending

7.Forming

8.Trimming

9.Flanging

The advantages of custom stamping process

Accuracy

Metal Stamping stands out of the crowd due to its remarkable repeatable precision. The detailed nature of this process allows us to manufacture metal shapes in the most complex forms while the possibility of error is minimal.

Cost efficiency

Metal Stamping allows a significant reduction of processing time while increasing the speed of production. Metal stamping reduces the use of multiple machines, the number of workers, as well as labour time which as a result significantly reduces production costs. This method is perfect for companies needing thousands of parts for bulk orders as it allows cost savings against other methods.

Automated process and additional value

When deciding on a high-volume job, you need to balance cost, quality, and volume. Metal stamping makes it very easy to complete high-volume work because of the automation process it entails. Not only is the process highly automated, but it can also incorporate secondary operations such as automatic nut insertion.

Which metal stamping process is right for your project?

Metal stamping is a popular manufacturing process for developing parts with tight tolerances using sheet metal, like steel, copper, stainless steel, and aluminum. You can take advantage of metal stamping to manufacture products across diverse industries such as:

1.Automotive

It plays a vital role in the automotive manufacturing industry — producing components such as body panels, brackets, chassis parts, engine mounts, brackets, and suspension components. The process ensures the production of lightweight, durable, and structurally sound parts that meet stringent safety and performance requirements.

2.Electronics

In the electronics industry, electronic devices (connectors, terminals, heat sinks, shielding components, and brackets) are widely used. Metal stamping made it possible for the precise fabrication of intricate parts required for electronic assemblies while ensuring proper electrical conductivity and durability.

Electronic Housing Stamping Part

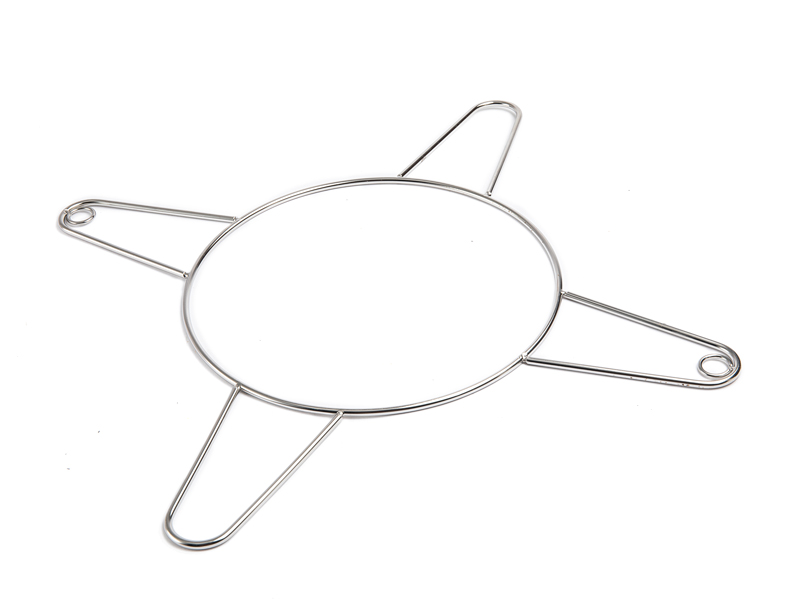

3.Home appliances

The process is also employed extensively in the manufacturing of household appliances like refrigerators, washing machines, ovens, and HVAC systems. It produces components such as panels, enclosures, brackets, and handles, providing both aesthetic appeal and structural integrity.

4.Healthcare Industry

In the medical field, devices such as surgical instruments, orthopedic implants, brackets, and connectors also have components that have undergone the metal stamping process ensuring the production of precise, sterile, and biocompatible parts critical for medical applications.

If you have any upcoming projects for stamping and need this technology.

Please contact us!

We can provide professional technology for stamping to help you.

Post time: Mar-19-2024