Overview of electroplating

In industry, we often hear about metal electroplating or electroplating craft.but do you really know about electroplating and how to use it to improve products? This article will clearly introduced information about electroplating to you.

Why choose abs electroplating technology

On the one hand the plastic electroplating product has the characteristic of plastic and metal, at the same time which has a small specific gravity, good corrosion resistance, simple molding, metallic luster and metallic texture, and electrical conductivity, magnetic permeability, and welding characteristics. According to this craft, it can save complicated process and avoid to waste expensive metal and is beautiful and decorative. Since the metal coating has high stability to external factors such as light, atmosphere, etc., after the plastic is plated with metal, it can prolong the service life of the plastic product. With industry develop, Electroplating technology is widely used in various fields, it has become the one of mean tool of surface decoration in plastic products. At present, it has been widely used to decorate surface of ABS, polypropylene, polycarbonate, polycarbonate, nylon, polystyrene, and other plastics. Among them, ABS plastic is the most widely used electroplating and the electroplating effect is the best.

What’s advantages of abs electroplating

Abs plastic has many characteristics of industry that make it become the first choose material for industrial applications, but it still has defect of low strength and easily affected by temperature and easily fretted and non-conducting. However after electroplating, abs plastic will gain new characteristics such as:

1.Strength

2.Structural integrity

3.Thermal resistance

4.Aesthetic appeal

5.Corrosion resistance

6.Durability and abrasion resistance

Electroplating can make any abs plastic has the characteristics of metal, at the same time professionals can remove deposit an adherent metal on the finishing through a chemical without mechanical abrasion,that can reduce time in process.

Application of abs electroplating

At recent, electroplating technology often used in making automotive parts. Due to the unique characteristics of ABS plastic, it can be made into any shape by designers, plus electroplating technology make it has the higher strength, therefore we often can see this technology apply in making automotive. Such as:grilles, light bezels, emblems, gear shift knobs, door handles and bumpers.

OTHER APPLICATIONS

Heat resistant products: Plastic parts exposed to extremely high temperatures during manufacturing or end use can be vulnerable to heat damage. A metal coating can act as a thermal shield that minimizes the risk.

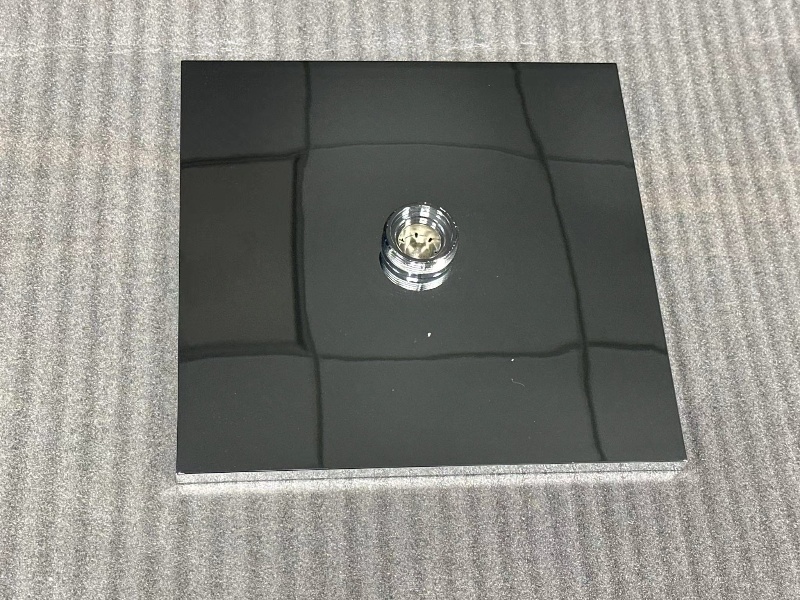

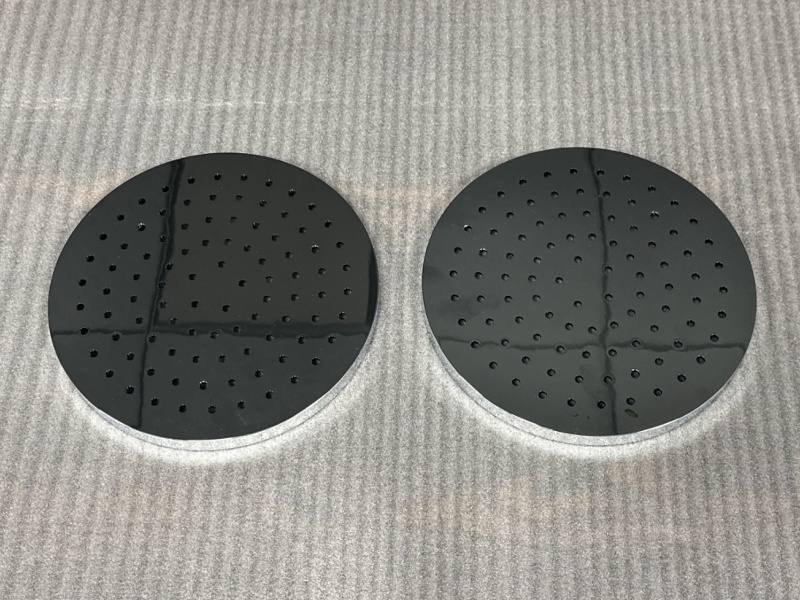

Bathroom products: Plating on plastics introduces sanitary qualities that are essential for products that require cleanliness and hygiene - a metal-plated plastic surface promotes easier, more efficient cleaning. Examples of products that fit this application include shower fittings, kitchen and bathroom accessories and washbasin taps.

Household products: You can often find plated metal on the knobs and controls installed on various household appliances and electronic devices. Using metal-coated plastic is less expensive than manufacturing all-metal knobs and more safe.

If you have any upcoming projects for abs electroplating and need this technology. Please contact us! We can provide professional technology for electroplating to help you.

Post time: Mar-15-2024