apid injection moulding is a versatile technology that can be used to produce a wide variety of parts and products. The process is fast and efficient, and can be used to produce parts with complex geometries. Rapid injection moulding is also an ideal solution for prototyping and low-volume production runs.

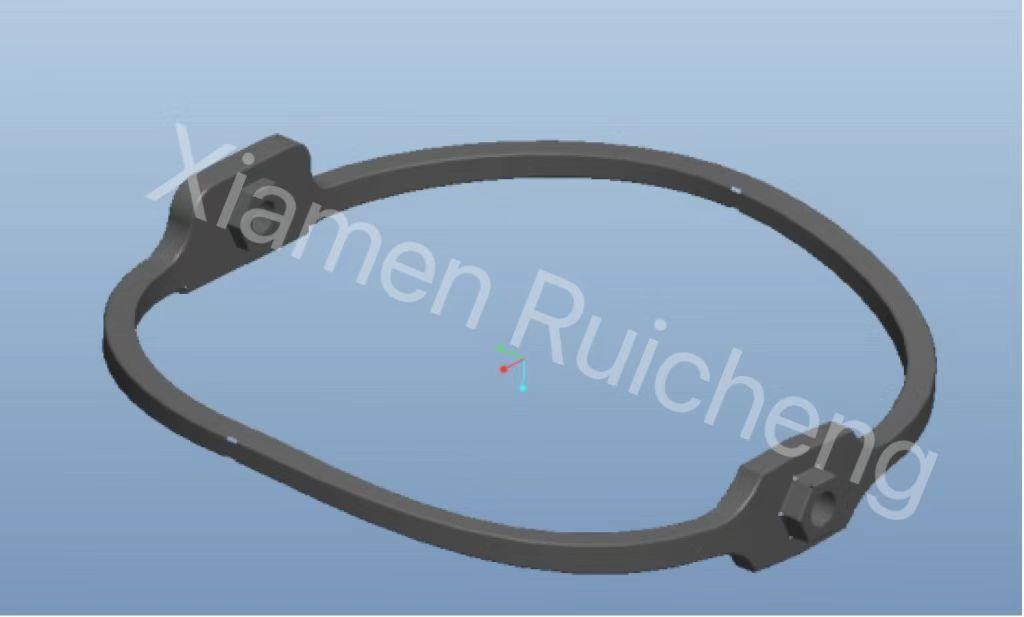

One of our client sent an inquiry as the following recently:

Hi Lois,

I hope you're well?

Just wondering if you have injection moulded in Hytrel 7246 (72 shore) or Hytrel 6358 (63 Shore) before? It's a hard but flexible plastic.

Also, what is your current estimated lead time for producing a simple multi-cavity injection mould tool for prototyping purposes? We need to test a pre-production design in Hytrel material, but it is not the final production tooling. Is this something you can do?

Our Reply is Yes, it is totally within our capability.

Why this client would like to use the rapid injection moulding is a situation that when they just need few samples but have to use the exact same plastic material as mass production.

Therefore, we would like to conclude: Whether to use rapid injection mould has 4 main factors: lead time, cost, and acceptable quality and small quantity.

●Lead Time: Rapid tooling has a shorter production cycle time for products because they are manufactured faster. This is particularly useful for small batch production needs that are lead time sensitive.

●Cost: Rapid tooling is more cost effective than traditional formal injection tooling. Because it is a simplified process, it takes less time and requires less labor.

●Quality: Parts made by rapid tooling are typically less durable and have a shorter life than conventional tooling. However, the acceptable minimum quality has a positive impact on your profitability.

●Quantity: When a product needs only a few quantity but have to use the same injecting plastic material, rapid injection tooling is the only solution.

Some people may get have the doubt: Other manufacturing process like 3D printing/CNC machine prototype/ vacuum casting can result in faster prototypes, why not use them? The biggest difference between these rapid prototype technology and raid injection moulding lies in the rapid injection moulding can use the actual production plastic material, helping customers to get a clearer picture of whether these parts will meet standards when actually produced, allowing you to test and confirm that you have made the right material choices.

Besides, to use rapid injection tooling can test the future production parameters, by this way, engineers and designers are able to get a lot of previously unnoticed issues and implement redesigns or other measures to prevent problems with the final part.

If you are not sure whether the products you are developing now is suitable or not to use rapid injection tooling, Xiamen Ruicheng is here to get back you our one-stop solution after having your RFQ.

Post time: Dec-16-2022