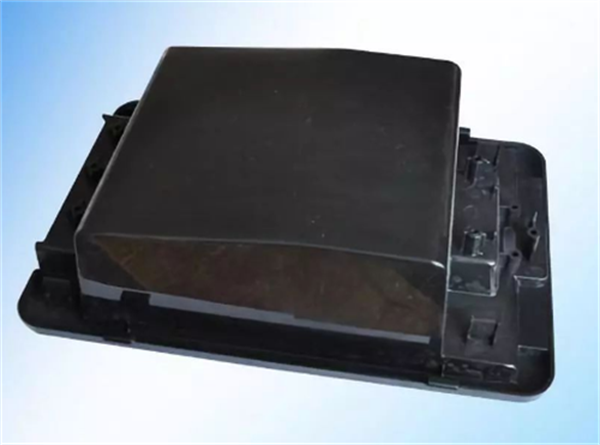

Warpage deformation refers to the distortion of the shape of the injection moulded product and warpage, deviating from the shape accuracy requirements of the part, it is one of the defects to solve in injection mould design and production.

What cause the issues and how to improve it?

The structure of the mould, the thermophysical properties of the plastic material and the conditions and parameters of the moulding process all have different degrees of influence on the warpage and deformation of the product.

1. Mould defects

The design of the mould determines the warpage tendency of the part, and it is very difficult to suppress this tendency by changing the moulding conditions, so the final solution must start from the mould design and improvement.

(1) Improving the mould so that the thickness and quality of the part is more uniform.

(2) the design of the cooling system to make the mould cavity temperature uniform in all parts, appropriate thickening of the more difficult to form part of the manifold, the main flow channel, shorten the flow distance, as far as possible to eliminate the cavity density difference, pressure difference, temperature difference.

(3) The transition area and corners of the thickness of the part should be smooth enough and have good mold release, such as increasing the release margin, improving the polishing of the mold surface, reducing the thickness of the frozen layer when filling the mold, reducing the internal stress and keeping the balance of the ejector system.

(4) To ensure good venting.

(5) Increase the wall thickness of the part or increase the warp resistance direction, by strengthening the reinforcement to enhance the warp resistance of the part.

2. Improper control of processing and moulding conditions

In the injection moulding process, molten plastic in the injection mould filling stage due to the arrangement of polymer molecules along the flow direction so that the plastic in the flow direction of the shrinkage rate than the vertical direction of the shrinkage rate, and the injection moulded parts warpage deformation (i.e. anisotropy). Generally, uniform shrinkage only causes changes in the volume of the plastic part, only uneven shrinkage will cause warpage deformation.

The injection pressure, rate and other parameters of the injection machine, filling and cooling stage of the temperature, pressure, speed of the three coupled with each other, the injection process, the temperature difference between different regions caused by thermal stress, thermal deformation or uneven shrinkage resulting in bending moment, may make the plastic parts warpage deformation

(1) Reduce the injection pressure and shorten the holding time to ensure sufficient temperature of the melt to avoid warpage due to increased internal stress.

(2) Reduce the mould temperature and increase the cooling time to avoid overheating of the part during demoulding and ejection deformation.

(3) Reduce screw speed and back pressure to reduce density while maintaining a minimum charge to limit internal stresses.

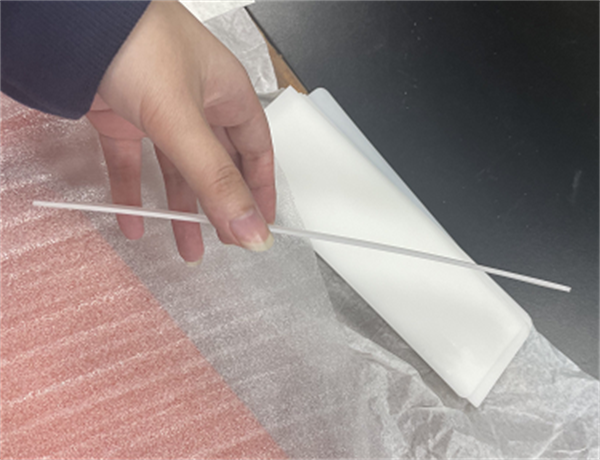

(4) If necessary, soft mould shaping or demoulding after demoulding can be carried out for parts that are prone to warpage and deformation.

When injection molding, there will be many problems, Xiamen Ruicheng has more than 20 years experience in this field, which can give you technical support and help. Would you like to know more? Contact us now!

Post time: Feb-03-2023